Preparation method of powder metallurgy

(1) Powder production. The production process of powder includes powder preparation, powder mixing and other steps. In order to improve the formability and plasticity of powder usually add oil, rubber or paraffin and other plasticizers.

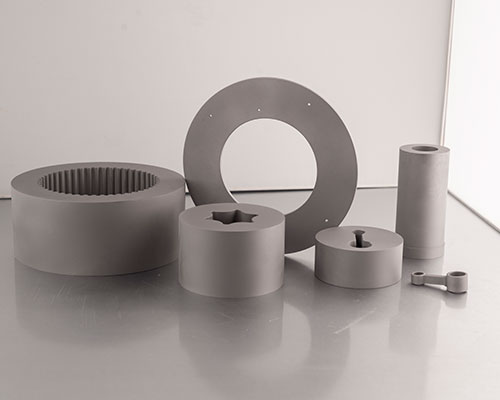

(2) pressing molding. The powder is pressed into the desired shape under 15-600MPa pressure.

(3) sintering. In the protective atmosphere of high temperature furnace or vacuum furnace. Sintering differs from metal melting in that at least one element remains solid during sintering. Through a series of physical and chemical processes, such as diffusion, recrystallization, fusion welding, combination and dissolution, powder particles become metallurgical products with certain porosity in the sintering process.

(4) Post-processing. Under normal circumstances, sintered parts can be used directly. But for some size requirements of high precision and high hardness, wear resistance of the parts should be sintered after processing. Post-treatment includes fine pressing, rolling, extrusion, quenching, surface quenching, oil immersion, and melting, etc.

Preparation method of powder

Preparation of powder is the first step of powder metallurgy. Powder metallurgy materials and products are increasing and their quality is improving. More and more kinds of powders are required. For example, from the perspective of material range, not only metal powder is used, but also alloy powder, metal compound powder, etc.; From the appearance of the powder, it is required to use a variety of shapes of powder, such as the generation of filters, it is required to form powder; From the point of view of powder size, requires a variety of particle size powder, coarse powder particle size of 500~1000 microns ultrafine powder particle size is less than 0.5 micron and so on.

In order to meet the various requirements of powder, there are various methods of producing powder which involve nothing more than the conversion of a metal, alloy, or metal compound into a powder state as a solid, liquid, or gaseous state. Various methods of preparing powder and various methods of powder.

Methods for transforming metals and alloys or metal compounds into powders in a solid state include:

(1) From solid metal and alloy to make metal and alloy powder with mechanical crushing method and electrochemical corrosion method:

(2) Reduction process for the preparation of metal and alloy powder from solid metal oxides and salts Reduction-chemical process for the preparation of metal compound powder from metal and alloy powder, metal oxides and non-metallic powder

Methods of turning metals and alloys or metal compounds into powders in liquid form include:

(1) Atomization of alloy powder prepared from liquid metals and alloys

(2) Preparation of metal alloy and coated powder from metal salt solution replacement and reduction, including replacement method and solution hydrogen reduction method; Molten salt aging process for preparing metal powder from metal molten salt precipitation; Metal bath process in which powder of metal compounds is precipitated from an auxiliary metal bath.

(3) electrolysis of metal and alloy powder from metal salt solution electrolysis with aqueous solution; Molten salt electrolysis process for producing powders of metals and metal compounds from molten salt electrolysis.

A method of turning a metal or metal compound into a powder:

(1) There is steam condensation method for making metal powder from metal steam condensation;

(2) carbon-based thermal dissociation of metals, alloys and coated powders from gaseous carbon substrates

(3) Gas phase hydrogen reduction of metal and alloy powder and metal and alloy coating from gaseous metal halides; Chemical vapor deposition of metallic compound powders and coatings from the deposition of gaseous metal halides.

However, from the essence of the process, the existing methods can be generally summarized into two categories, namely mechanical method and physical chemical method. Mechanical method is the mechanical grinding of raw materials, and the chemical composition basically does not change the process; Physicochemical method is the process of changing the chemical composition or aggregation state of raw materials with the help of chemical or physical action to obtain powder. The production methods of powder are many from the industrial scale. Some methods such as the Hans reduction method, atomization method and electrolysis method are widely used, such as vapor deposition method and liquid deposition method are also very important in special applications.